4 Things you need to know about warehouse lighting

Busy working environments, like warehouse and distribution centres need adequate lighting to ensure that all workers are operating within a safe environment.

1) Dramatically reduce your project costs through good lighting design and rebates

Whilst this seems obvious, it may not be as simple as just replacing the fitting, especially if racking systems are already in place. Poorly arranged lighting installations waste energy and reduce luminance levels as light is delivered to the wrong place.

The spacing of your light fixture is critical. If they are positioned too close together, you will experience hot spots and glare where one light fixture overlaps the next. If spaced too far apart, you'll get dark areas. Warehouses can have complex lighting requirements, so to achieve the best result it is essential to get a lighting design for your premises.

An optimised lighting solution includes having adequate lighting and uniformity for each area and task. Dramatically reduce your costs through good lighting designs and rebates. Government rebates are available for upgrading to energy efficient LED lights in NSW, VIC and SA...Start saving today!

TAKE ADVANTAGE OF MASSIVE REBATES (A logistic center example)

| Illuminance | Use of Space | Application |

| 40 lux | Rarely visited spaces with visual tasks limited to movement and orientation | Warehouse - rarely visited storage of bulky materials, storage of one of a kind large size material, corridors, passageways and ramps |

| 80 lux | Intermittent use, visual tasks limited to movement, orientation and coarse detail | Warehouse - storage of bulky materials, storage of goods involving search and retrieval tasks such as loading bays or storage rooms. |

| 160 lux | Continuously occupied, coarse detailed work and occasional reading of clear print | Warehouse - rough stock check, storage of medium/fine material, reading of labels; packing and dispatch of large objects. General work such as non detailed bench and machine work. Counting, cleaning, entrance halls, automated process monitoring, gas and arc welding; cafeteria's. |

| 240 lux | Continuously occupied, moderately easy tasks with high contrast or large detail | Packing and dispatch of medium sized goods. General work such as transaction counters, rough woodwork, food preparation, cooking, washing up, general sheet metal works. |

| 400 lux | Moderately difficult visual tasks with low contrast or moderate detail | Packing and dispatch of small goods. General work such as medium grade bench and machine work, inspection and sorting of goods, spot welding and standard woodworking. |

Obtain expert advice: enLighten offers quality lighting designs.

2) Check the optics

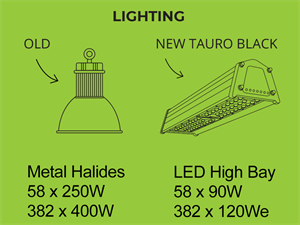

On the market now is the next generation of LED high bays, they are 40% more efficient than current standard LED high bays. Using symmetric and asymmetric lens allows for the delivery of custom light patterns that suit the varied work areas.

The Tauro Black high bay offers good vertical lighting and eliminates waste light

Aisle racking requires quality vertical illumination that is evenly distributed to reduce picking errors. For general warehouse logistic areas, uniform horizontal light is required to maximise visibility and improve safety.

Ensure you are choosing the right lights for the application. High bay lighting solutions are effective for lighting warehouses however there are many options with different configurations that you should take into consideration.

3) Avoid glare for fork-lift truck drivers

LED arrays have a point intensity of each LED chip, which can make glare a serious problem if workers are required to look upwards into the luminaire face. This can be a problem for fork truck drivers when they need to stack the higher shelves. There is often a trade off with higher efficacy and visual comfort.

Speak to your lighting specialist about what lighting solution is best suited to your environment.

4) Don't turn the lights on when you don't need them

Warehouses can have complex lighting requirements as they have high ceilings and can leverage natural light from skylights and open roller doors. Using an integrated occupancy and daylight sensor ensures proper area illumination and increases energy savings by up to 30%.

When activity is detected, the light levels go up instantly to the requirements of the area. After a period of inactivity the sensor turns the light fixture off or dims them to a pre-set level, this achieves additional energy savings.

As a simple rule: Don't turn the lights on when you don't need them.

Technical Articles

Help us tailor your experience

We’d love to better understand who’s visiting. This isn’t data collection, just a quick way to help us design a better site for you.