Date published: 10/04/2024

In 2020, the Telstra InfraCo embarked on a bold mission towards environmental responsibility and sustainability, setting ambitious targets:

- Reduce CO2 emissions by 50% by 2030.

- Achieve an 85% waste recycling rate by 2025.

One of the projects identified to achieve these targets was upgrading the lighting in hundreds of Telstra InfraCo Exchanges, some over a century old. Whilst the function of the Telstra InfraCo Exchange has changed over time their importance has not diminished, and as well as providing modern telephone exchanges, they now play a key role in hosting critical infrastructure equipment for several service providers.

The scale and geographic spread of this project required a radically different approach compared to the smaller single site lighting upgrade that most organisations undertake.

Project Management appointment

In July 2020, enLighten Australia was appointed as the lighting designer, product supplier, and project manager for the first stage of the Telstra InfraCo Exchange LED Lighting program. The contract was a combination of delivering on the CO2 reduction targets set for the project and to redesign the lighting that would result in optimising the number of lights in each facility by 40%.

Project Scope and Challenges

Upgrading LED lighting across hundreds of sites spread across the Eastern Seaboard, was a significant undertaking. This necessitated a new project delivery strategy, with contractor management and logistics at its core. To solve these challenges, we established a multi-skilled project team to project manage the delivery program.

Our first step was to document the work and ensure that we were covering all possible scenarios that may exist in an Exchange. This document was the foundation for a training program for the contractors and auditors. The next challenge was to find contractors who could work autonomously in every location, organisations capable of delivering luminaires to sites across Australia, and certified recycling centres that could sustainably treat the waste.

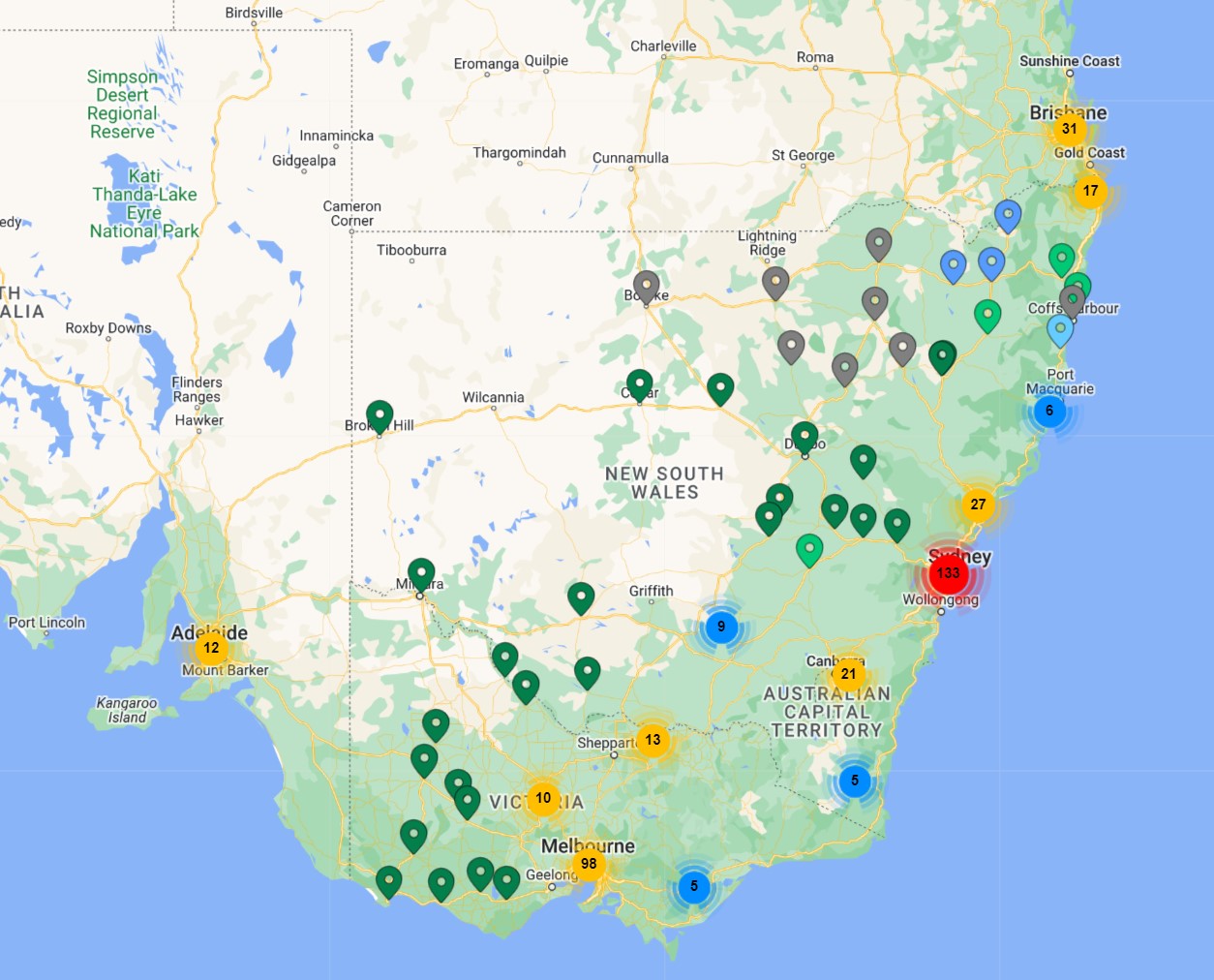

The location of hundreds of Telstra InfraCo sites spread across the Eastern Seaboard

Establishing a safe work area

Ensuring safety on site when storing material

The project team also undertook lighting designs, created new asset schedules, and ensured workplace Health, Safety and Quality audits were undertaken. Cloud-based software was used to streamline these tasks and assist with data management and reporting.

With effective planning and dynamic problem-solving, Telstra was getting closer to its sustainability goals.

Key Features and Innovations

The contract between enLighten and Telstra InfraCo was structured around delivering emission reductions and meeting recycling objectives. enLighten’s responsibilities spanned the entirety of the project:

- Project management

- Lighting design

- Luminaire delivery

- Logistical management

- Project metric tracking

enLighten approached Telstra InfraCo to discuss the innovative delivery model that ensured Telstra’s InfraCo’s objectives were prioritised without undue burden on layers of reporting and approvals. This resulted in enLighten becoming contractually responsible to maximise lighting optimisation. It permitted flexibility around project delivery and used technology to ensure governance and fiscal control was retained by Telstra InfraCo – both of which were pivotal to the project’s success. Key innovations enLighten introduced to the project included:

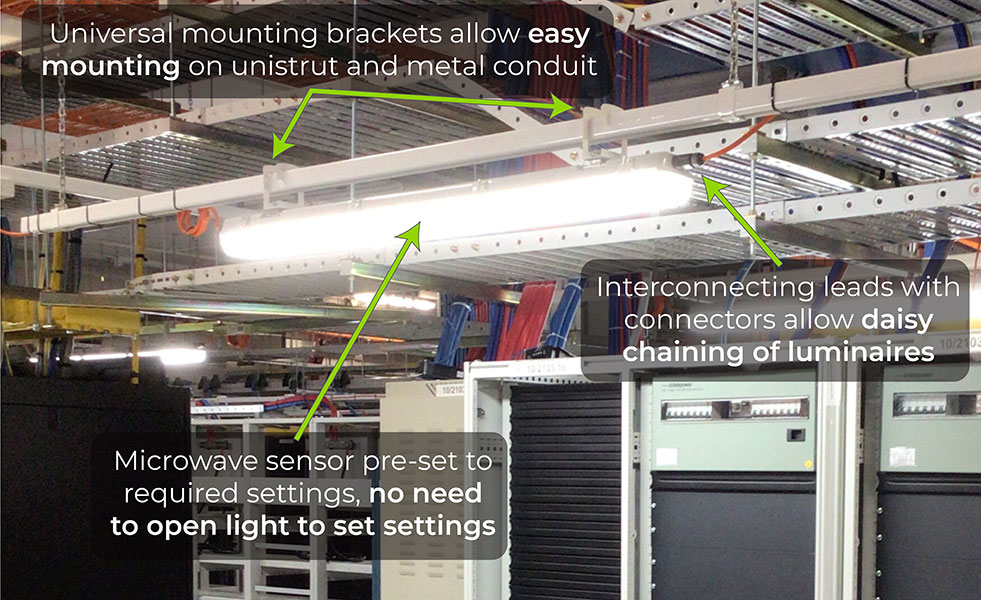

- The design of a new luminaire mounting system that integrated with the existing superstructure within the exchanges, making installation easier, enhancing efficiency, and reducing Workplace Health and Safety (WHS) risks.

- Designing eco-conscious packaging for the luminaires, minimising waste while facilitating easy reuse for waste removal.

- Developing installation guides that contractors could easily understand, resulting in a 50% increase in lighting optimisation.

- Developing a customised project management system that supported the project planning, contractor management and auditing. This system also tracked all the recycling and the luminaries that were installed as part of the project.

Streamlined luminaire connection system for effortless installation and maximised energy savings.

Vico battens packaged in sets of four to reduce waste and labour.

Project Delivery

Once the project structure was agreed, enLighten designed a bespoke end to end process and built software to enable strong controls over the project by key stakeholders.

While the project team organised logistics and contractor training; the manufacture and supply of tens of thousands of luminaires were underway. Multiple hubs were created in strategic locations to store and distribute the fixtures to sites.

Meeting the project timeframes required back-to-back scheduling of the upgrade works, with minimal downtime. This demanded a well-coordinated dispatch of lighting fixtures to adhere to the rollout schedule.

As the project progressed, the project team maintained close collaboration with our contracting partners and logistics providers, continuously fine-tuning our delivery processes.

Our project team conducted regular site audits for quality assurance and workplace safety to guarantee the project adhered to the objectives and maintained the safety standards expected by both Telstra InfraCo and enLighten.

Regular meetings between Telstra InfraCo and the project team ensured the project stayed on track and addressed any on-site challenges.

Project Outcomes

The project teams’ primary mission was clear: achieve carbon emission reduction targets. This demanded a high level of lighting optimisation to reduce the number of lights compared to those being replaced.

Our initial objective was to reduce the number of lights by 40%, and we exceeded expectations with a reduction result closer to 53%.

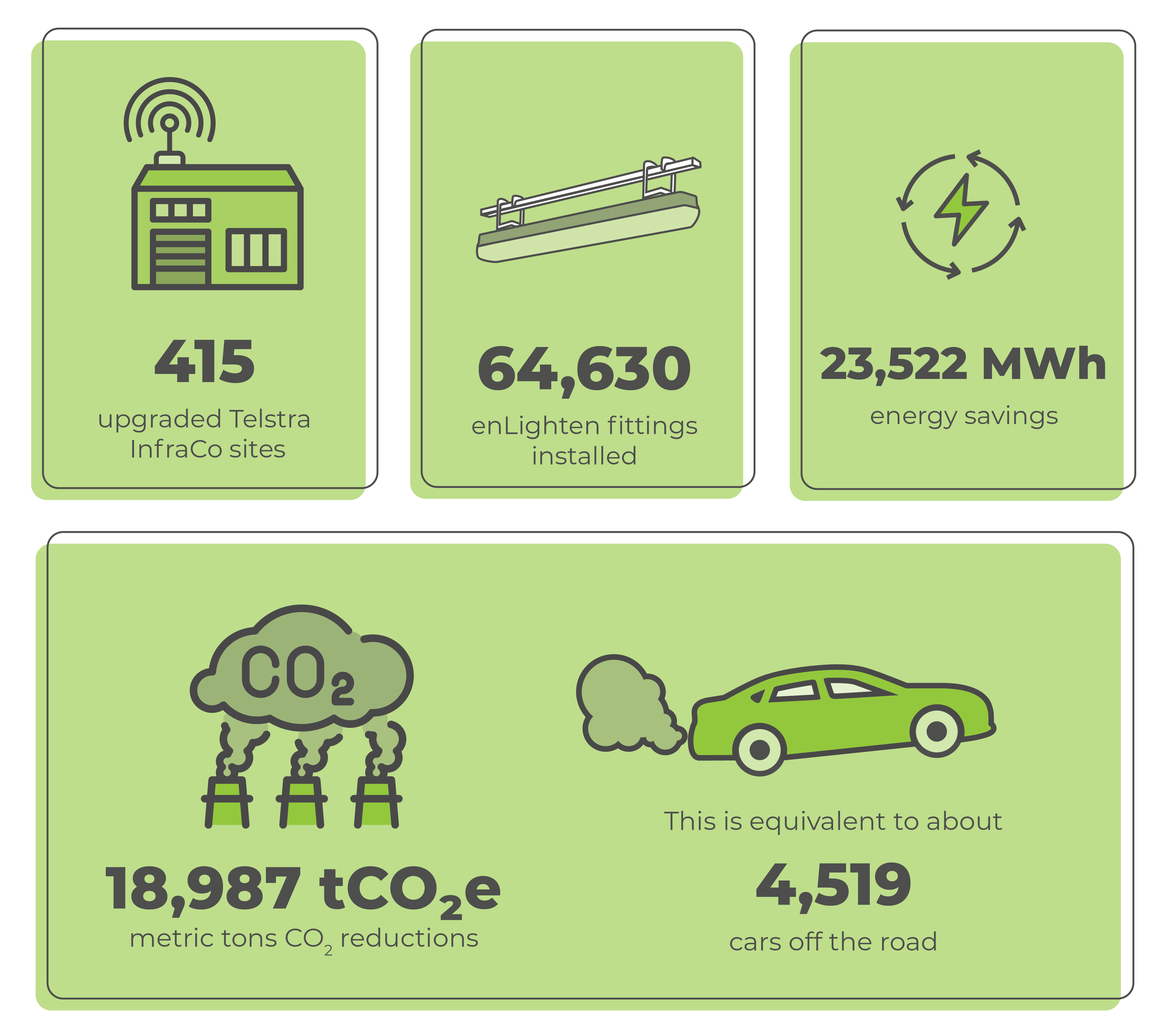

Simultaneously, we strategically installed 64,630 enLighten fittings to maximise illumination while minimising energy consumption. This achievement not only met carbon reduction targets but also maximised the available energy rebates from both the Victoria and New South Wales energy-saving schemes. At the halfway mark, 415 sites had been upgraded, leading to a reduction of 18,987 metric tons of carbon dioxide equivalent emissions (TCO2e) per annum.

Recycling Results

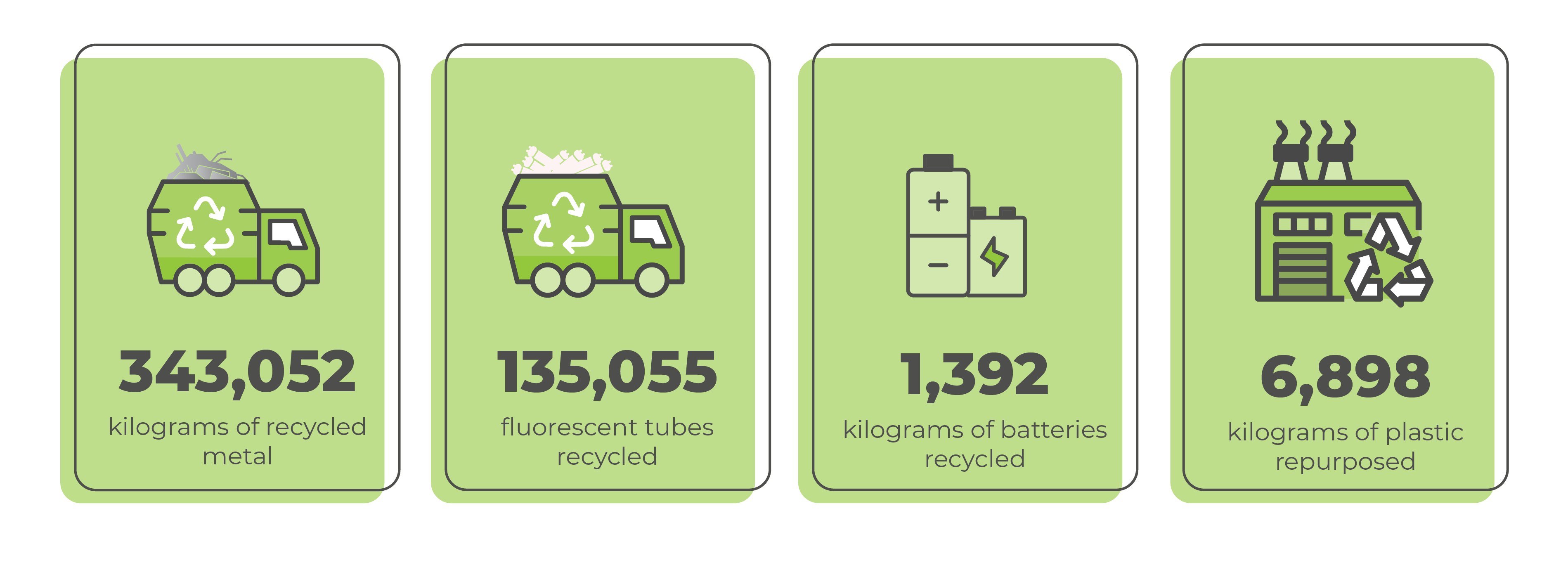

The secondary objective was to record and document the recycling of waste materials from each site. Identifying compliant recycling facilities, especially in remote areas, was one of the challenges of this project. The volume of materials recycled was astonishing:

- 343,052 kilograms of recycled metal

- 135,055 fluorescent tubes

- 1,392 kilograms of batteries

- 6,898 kilograms of plastic

These results assisted Telstra InfraCo with their ESG reporting.

Recycling from various exchanges

Conclusion

This case study showcases the advantages of clients collaborating closely with suppliers to establish performance-based metrics. The results speak for themselves, demonstrating the successful delivery of Australia’s largest energy efficiency lighting upgrade project and assisting Telstra InfraCo in delivering their ambitious CO2 reduction target.